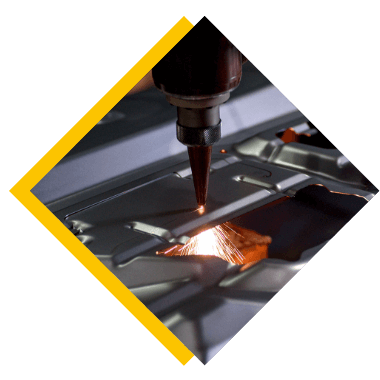

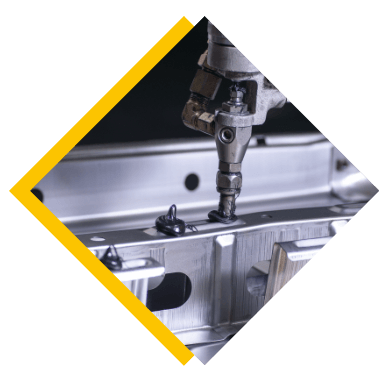

Gordon 's key advantage in producing for the high-end market is our well-trained team of experienced mold building and tooling calibration technicians. However, to compete in the fast changing global market, Gordon acquired high-technology equipment to upgrade its capacity and capability. Fit is the most important aspect of a replacement part. Stringent variance analysis, using coordinate measuring machines (CMMs) & vehicle test fits (VTFs), validates that the best OEM sample part has been chosen as a master for reverse engineering and used to develop an exact prototype of the original. Once chosen, precision scanning machines are used to obtain the digitized data of the OEM sample part. Using the CAD/CAM automated design system, an original male or female mold is produced based on the digitized data of the model generated by the scanning machines. When the data passes through the workstations, the original outline is smooth and restyled. Decoration is then added by cutting along the outlines.

For the quality and consistency of production, Gordon takes samples to conduct a series of testing and analysis: